Bread is a key food staple in most households around the world. The United States consumes over 13 tons of bread each year, followed by Russia consuming over 8.7 tons, and Germany with 6.3 tons. Freshly baked bread comes in many forms, from baguettes, pan de leche, naan, biscuits, bagels, pretzels, to mantou, and so on.

As consumers, bread is available to us in most grocery stores and restaurants whenever we want it. But what we may not know about is the complex process of the bread business. So how does fresh bread make it to grocery stores every day?

I had the pleasure to learn from one of the leading bread manufacturers – George Weston Foods (GWF). They pride themselves on delivering freshly baked goods to their expanded grocery store network each day and removing day-old bread from the shelves to ensure the highest quality for its customers.

Beyond flour and water

For over 50 years, GWF has not skipped a beat to delight their customers with bread. Their processes, however, needed to scale as demand grew and the number of grocery stores that carried their products increased. Multiple departments needed to coordinate with one another to fulfill and optimize demand. The manufacturing department needed to know how much bread to produce. At the same time, the finance team needed to know how much bread is being produced, shipped, returned, and sold by the grocery stores to balance out the books. With all facets of the company needing information to do their specific jobs, the operations and business development teams needed to streamline processes and find ways to grow the business.

Each team had their own tools and applications to help them analyze data and obtain answers. Although different teams used the same sets of data to perform the analysis, the results produced varied outcomes.

Achieving operational excellence with data

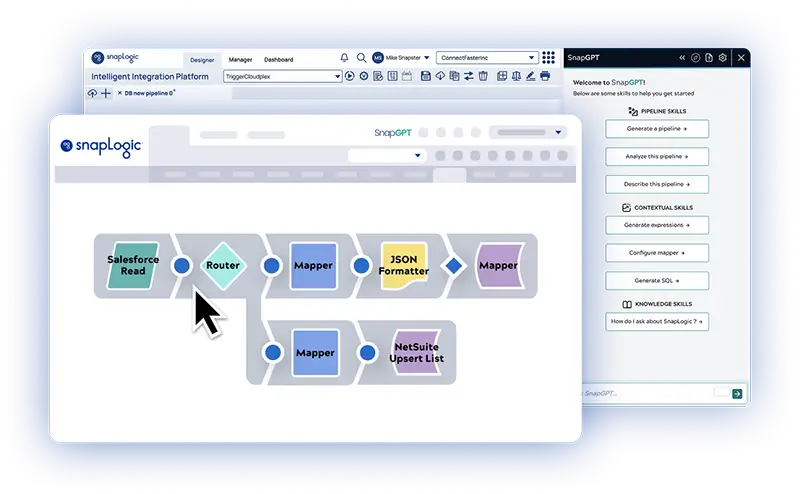

Needing insights pulled from consistent data across all tools, GWF formed a tiger team to solve the problem. The team quickly realized that they needed a way to consolidate data from their ERP and other business applications into a centralized cloud-based data warehouse. They discovered SnapLogic as their partner of choice to unify the company’s data.

The tiger team started building integrations a few hours after the setup, moving data amongst cloud applications and databases into their cloud data warehouse. Business teams could easily access relevant data sets from their analytics platform to build reports ranging from sales and finance to operations and supply chain metrics.

As their motto says, GWF delivers “really, really good food” to its customers. Now they deliver really, really good data to empower its business users. In some respects, maybe data is like bread. Companies need it to survive in today’s competitive world.

Read George Weston Food’s case study to learn how they improved their operational processes.